Manufacturing Companies for Super Enamelled Copper Wire - Manufacturer high quality enameled 50% cca copper clad aluminum wire for motor winding – Shenzhou Detail:

Model introduction

|

Model introduction |

||||||||

|

Product Type |

PEW/130 |

PEW/155 |

UEW/130 |

UEW/155 |

UEW/180 |

EIW/180 |

EI/AIW/200 |

EI/AIW/220 |

|

General Description |

130Grade Polyester |

155Grade Modified Polyester |

155Grade Solderability Polyurethane |

155Grade Solderability Polyurethane |

180Grade Straight Welded Polyurethane |

180Grade Polyester Imine |

200Grade Polyamide imide compound polyester imide |

220Grade Polyamide imide compound polyester imide |

|

IEC Guideline |

IEC60317-3 |

IEC60317-3 |

IEC 60317-20, IEC 60317-4 |

IEC 60317-20, IEC 60317-4 |

IEC 60317-51,IEC 60317-20 |

IEC 60317-23, IEC 60317-3, IEC 60317-8 |

IEC60317-13 |

IEC60317-26 |

|

NEMA Guideline |

NEMA MW 5-C |

NEMA MW 5-C |

MW 75C |

MW 79, MW 2, MW 75 |

MW 82, MW79, MW75 |

MW 77, MW 5, MW 26 |

NEMA MW 35-C |

NEMA MW 81-C |

|

UL-Approval |

/ |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

|

Diameters Available |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

|

Temperature Index (°C ) |

130 |

155 |

155 |

155 |

180 |

180 |

200 |

220 |

|

Softening Breakdown Temperature(°C) |

240 |

270 |

200 |

200 |

230 |

300 |

320 |

350 |

|

Thermal Shock Temperature(°C) |

155 |

175 |

175 |

175 |

200 |

200 |

220 |

240 |

|

Solderability |

Not weldable |

Not weldable |

380℃/2s Solderable |

380℃/2s Solderable |

390℃/3s Solderable |

Not weldable |

Not weldable |

Not weldable |

|

Characteristics |

Good heat resistance and mechanical strength. |

Excellent chemical resistance; good scratch resistance; poor hydrolysis resistance |

Softening breakdown temperature is higher than UEW/130; easy to dye; low dielectric loss at high frequency; no salt water pinhole |

Softening breakdown temperature is higher than UEW/130; easy to dye; low dielectric loss at high frequency; no salt water pinhole |

Softening breakdown temperature is higher than UEW/155; straight soldering temperature is 390 °C; easy to dye; low dielectric loss at high frequency; no salt water pinhole |

High heat resistance; excellent chemical resistance, high heat shock, high softening breakdown |

High heat resistance; thermal stability; cold-resistant refrigerant; high softening breakdown; high thermal shock |

High heat resistance; thermal stability; cold-resistant refrigerant; high softening breakdown; high heat rush |

|

Application |

Ordinary motor, medium transformer |

Ordinary motor, medium transformer |

Relays, micro-motors, small transformers, ignition coils, water stop valves, magnetic heads, coils for communication equipment. |

Relays, micro-motors, small transformers, ignition coils, water stop valves, magnetic heads, coils for communication equipment. |

Relays, micro-motors, small transformers, ignition coils, water stop valves, magnetic heads, coils for communication equipment. |

Oil-immersed transformer, small motor, high-power motor, high-temperature transformer, heat-resistant component |

Oil-immersed transformer, high-power motor, high-temperature transformer, heat-resistant component, sealed motor |

Oil-immersed transformer, high-power motor, high-temperature transformer, heat-resistant component, sealed motor |

IEC 60317(GB/T6109)

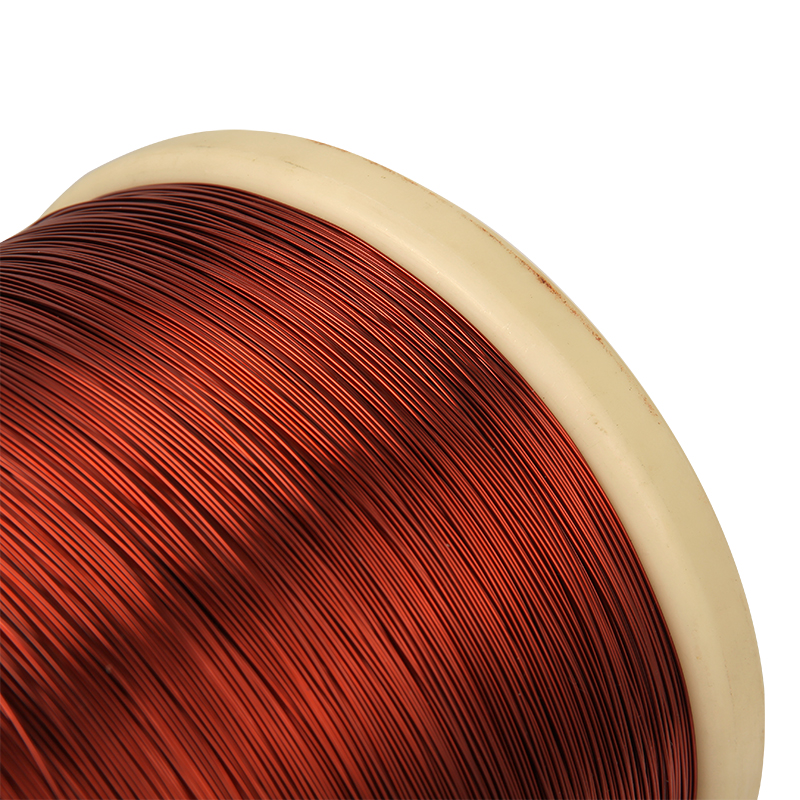

Precautions for use USAGE NOTICE

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Manufacturing Companies for Super Enamelled Copper Wire - Manufacturer high quality enameled 50% cca copper clad aluminum wire for motor winding – Shenzhou , The product will supply to all over the world, such as: Bhutan, Marseille, United Arab emirates, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!