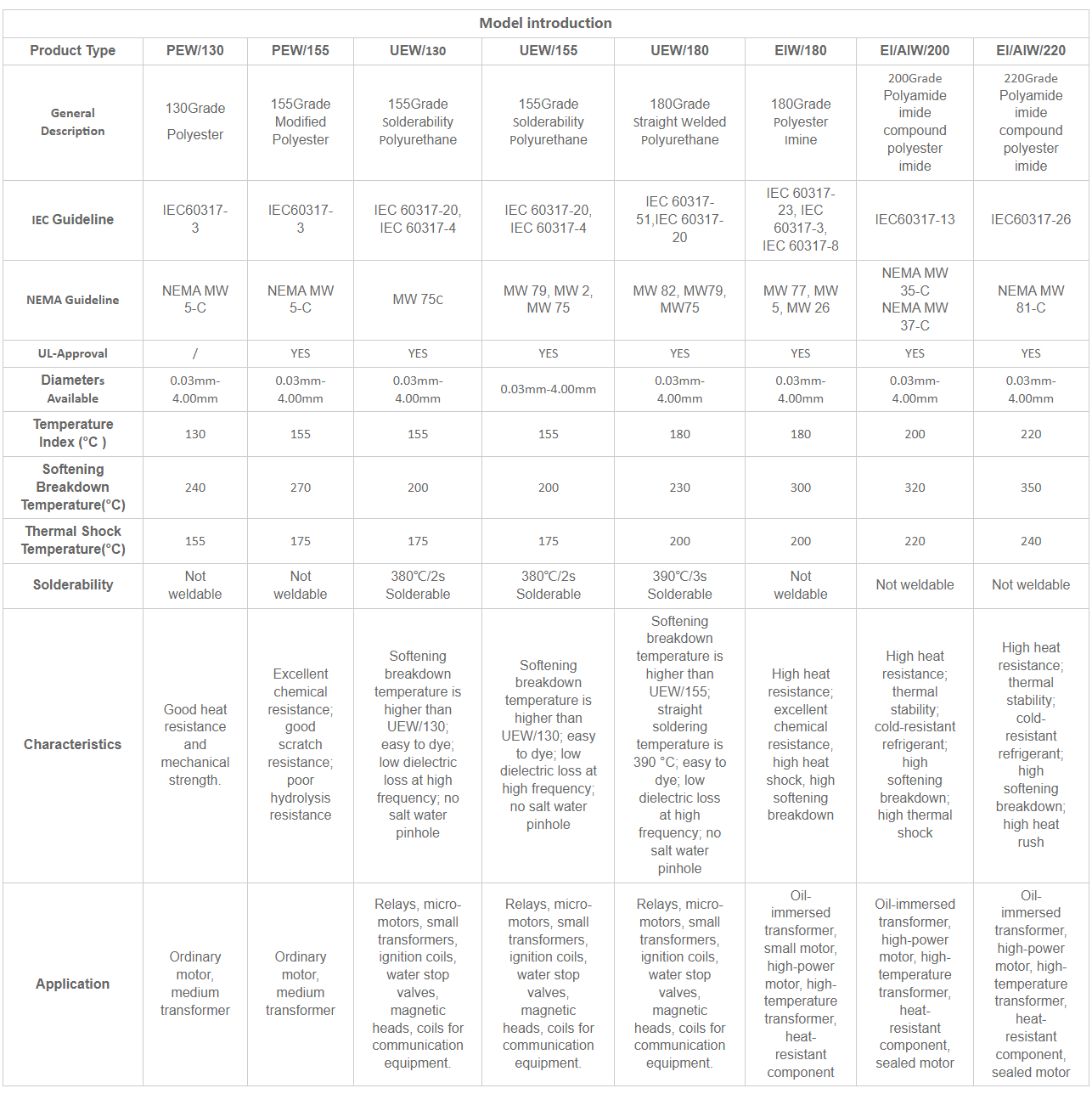

Gabatarwar samfuri

Cikakken Bayani

IEC 60317 (GB/T6109)

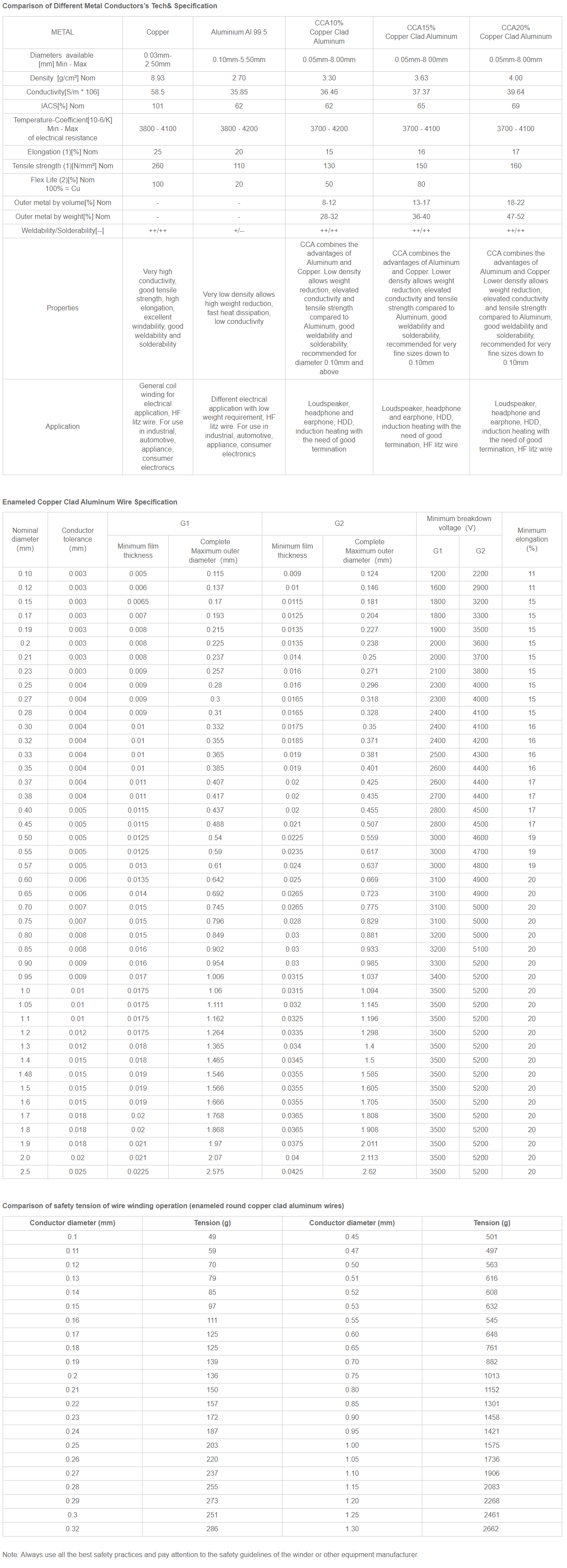

Ma'aunin Tech & Specification na wayoyi na kamfaninmu suna cikin tsarin naúrar ƙasa da ƙasa, tare da naúrar millimeter (mm). Idan kayi amfani da Ma'aunin Waya na Amurka (AWG) da Ma'aunin Waya na Biritaniya (SWG), tebur mai zuwa shine tebur kwatance don tunani.

Mafi girman girma na musamman za a iya keɓance shi gwargwadon buƙatun abokan ciniki.

Kariya don amfani SANARWA

1. Da fatan za a koma zuwa gabatarwar samfurin don zaɓar samfurin samfurin da ya dace da ƙayyadaddun bayanai don guje wa gazawar yin amfani da su saboda halaye marasa daidaituwa.

2. Lokacin karɓar kaya, tabbatar da nauyi kuma ko akwatin marufi na waje ya murƙushe, ya lalace, ya lalace ko ya lalace; A cikin aikin sarrafa shi, ya kamata a kula da shi da hankali don guje wa girgiza don sa kebul ɗin ya faɗi gaba ɗaya, wanda ya haifar da babu kan zaren, waya mai makale kuma babu saiti mai santsi.

3. Lokacin ajiya, kula da kariya, hana lalacewa da niƙa da ƙarfe da sauran abubuwa masu wuya, da kuma hana haɗaɗɗen ajiya tare da sauran ƙarfi, acid mai ƙarfi ko alkali. Ya kamata a nannade samfuran da ba a yi amfani da su sosai kuma a adana su a cikin ainihin fakitin.

4. Ya kamata a adana wayar enameled a cikin ma'ajiyar iska mai nisa daga ƙura (ciki har da ƙurar ƙarfe). An haramta hasken rana kai tsaye don guje wa yawan zafin jiki da zafi. Mafi kyawun yanayin ajiya shine: zazzabi ≤50 ℃ da dangi zafi ≤ 70%.

5. Lokacin cire enameled spool, haɗa yatsan hannun dama da yatsan tsakiya zuwa ramin farantin ƙarshen ƙarshen, kuma riƙe farantin ƙarshen ƙarshen tare da hannun hagu. Kada ka taɓa wayar enameled kai tsaye da hannunka.

6. A lokacin aikin iska, ya kamata a saka spool a cikin murfin biya har ya yiwu don kauce wa lalacewar waya ko gurɓataccen ƙarfi; A cikin aiwatar da biya kashe, da winding tashin hankali ya kamata a daidaita bisa ga aminci tashin hankali tebur, don haka don kauce wa waya breakage ko waya elongation lalacewa ta hanyar wuce kima tashin hankali, da kuma a lokaci guda, kauce wa waya lamba tare da wuya abubuwa, sakamakon fenti film lalacewa da kuma matalauta short kewaye.

7. Kula da maida hankali da adadin sauran ƙarfi (methanol da anhydrous ethanol ana bada shawarar) a lokacin da bonding da sauran ƙarfi bonded kai m line, da kuma kula da daidaita da nisa tsakanin zafi iska bututu da mold da zafin jiki lokacin bonding zafi narke bonded kai m line.